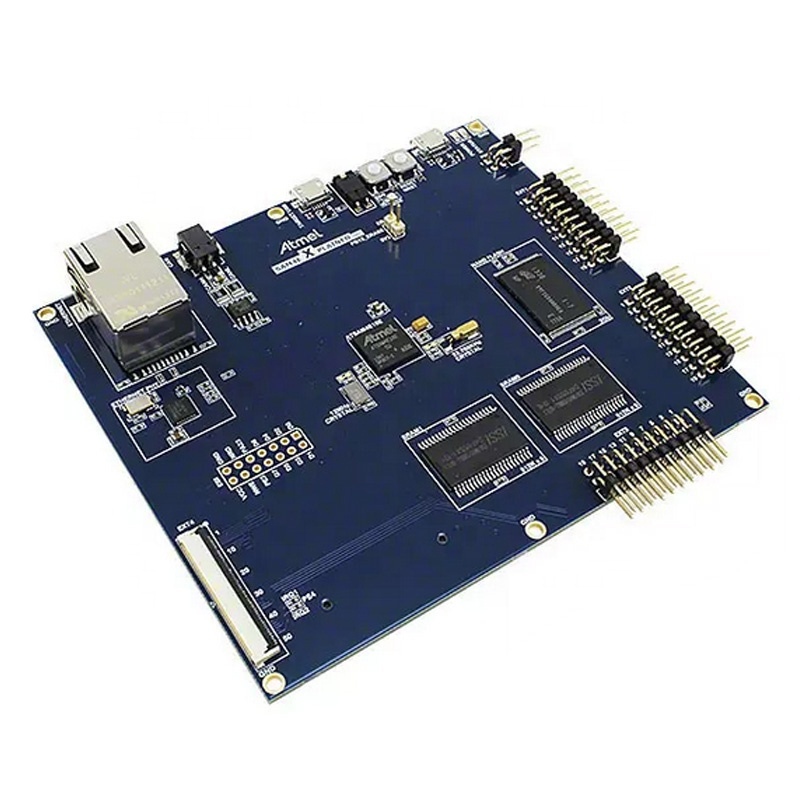

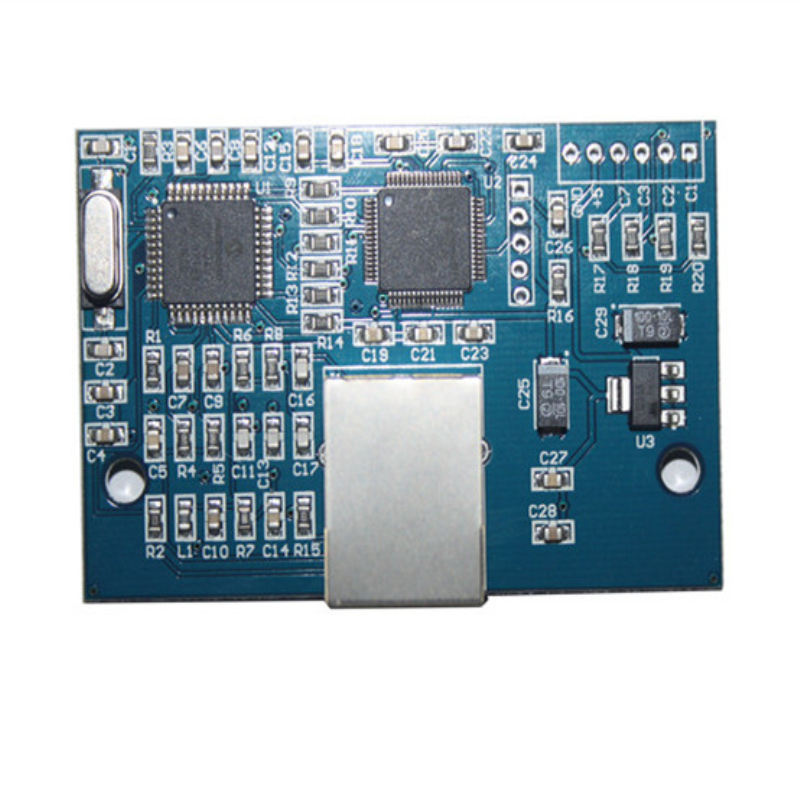

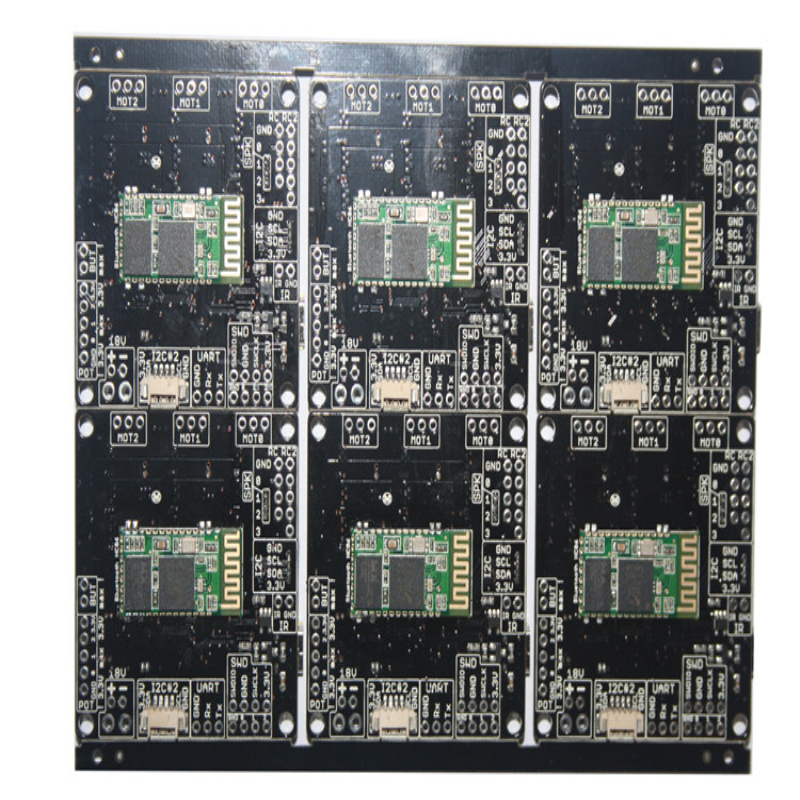

Surface Mount &BGA Assembly

Product Description

What is BGA assembly?

(1) In the work of Surface-Mount (SMT) & BGA Assembly, it is also very important for the viscosity of the flux used for SMT to be very high. Too high will affect the coating and transfer; too low will affect the amount of coating. Generally, the viscosity should be selected in the range of (25000±5000)cp.

(2) The thickness of the flux is 60% of the solder ball. If it is too thick, it is easy to be smeared on the package body, causing vibration during soldering, and even optical centering recognition.

(3) Detection method. Generally, a saw tooth ruler can be used for detection, but this saw tooth ruler may have a height difference from the actual BGA chip solder ball due to factors such as sampling position, operation method (immersion speed, time), and saw tooth size.

Glass paste should be used for observation. A good solder height should obtain a uniform solder pattern under the glass plate, and the size should be at least larger than the solder ball. The device that rotates and smoothes the flux often obtains a different amount of flux due to the difference in viscosity. Using X-rays to observe the size of the solder joints, it is found that the thicker the flux, the larger the diameter of the solder joint, indicating that the amount of flux affects the degree of collapse of the solder joint. Tests show that the coating thickness should reach 60% of the diameter of the solder ball

(4) BGA packages should use large-size balls to eliminate bridging caused by the sealing effect after excessive flux.

(5) The source of the formation process of solder joints and the video of PCB reflow soldering process. When the ML-PoP is heated above the melting point of the solder joint, the BGA solder ball and the PoP solder ball will melt and fuse successively.

The early fusion will be drawn into a columnar or waist shape, and then as most of the solder joints are fused, the Surface-Mount (SMT) & BGA Assembly will fall.

From this process, the melting and fusion process of the BGA solder ball and the PoP solder ball is gradually completed. As long as there is flux on the BGA solder ball, the BGA solder ball and the PoP solder ball will fuse and will not form a ball socket; If there is no flux on the ball, a ball socket will be formed.

If there is flux on the bottom surface of the SMT & BGA Assembly, it will cause the BGA to vibrate up and down on the PoP. This vibration is beneficial to eliminate the discharge of gas inside and outside the fusion solder joints and the disconnection of the bridge solder joints in smt patch processing, and has the effect of eliminating bridging. PoP has never been bridging due to excessive flux, but excessive flux will affect the placement of a Surface-Mount & BGA Assembly. When the Surface-Mount & BGA Assembly is wetted with flux, the nozzle of the placement machine cannot absorb the components, and it also affects the pattern recognition

Product Categories : PCB Assembly Products > Surface-Mount (SMT) &BGA Assembly